Rubber accelerator DOTG

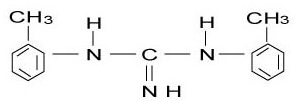

Chemical name: di-o-tolueneguanidine

Structural formula:

Molecular Formula: C15H17N3

Molecular weight: 239.32

CASE NO: 97-39-2

Product Specifications:

|

Metric name |

Powder |

Add oil powder |

grain |

|

Appearance (visual) |

Off-white powder (granules) |

||

|

The initial melting point ≥ °C |

170.0 |

170.0 |

170.0 |

|

Heating reduction %≤ |

0.30 |

0.50 |

0.30 |

|

Ash %≤ |

0.30 |

0.30 |

0.30 |

|

Sieve residue (150 μm), % ≤ |

0.10 |

0.10 |

- |

|

Sieve residue (63 μm), % ≤ |

0.50 |

0.50 |

- |

|

Additives,% |

- |

0.1-2.0 |

- |

|

Particle size, mm |

- |

- |

1.50 |

Properties: This product is gray-white powder, slightly bitter taste, odorless. Relative density: 1.01-1.02. Soluble in chloroform, acetone, ethanol, slightly soluble in benzene, insoluble in gasoline and water.

Uses: Can be used for NR, SNR, IIR, IR, SBR, NBR and CR. The activity is very similar to that of the accelerator D (diphenyl muscle). Low activity at operating temperature and safe operation. The critical temperature of vulcanization is 141οC, which is very active at the vulcanization temperature, especially when it is higher than the critical temperature, and the vulcanization flatness is good. This product is an important active agent of acid accelerator, especially thiazole and sulfonamide accelerator, and has the effect of super promoter with accelerator M. Mainly used for thick-walled products, tread glue, buffer layer, rubber roller covering glue, etc. The dosage is generally 0.8-1.5 parts when used as the first accelerator, and the dosage when used as the second accelerator of thiazole accelerator is 0.1-0.5 parts.

Packing: 25kg plastic woven bags, paper-plastic composite bags, kraft paper bags.

Storage: should be stored in a cool, dry, well-ventilated place. Packaged products should be protected from direct sunlight.

Rubber accelerator

Rubber antioxidant

Other rubber chemicals

Messages